China wholesale High Voltage Interrupter Factory – Vacuum interrupter for MV VCB, VS1 ZN28 ZN63 – Shone

China wholesale High Voltage Interrupter Factory – Vacuum interrupter for MV VCB, VS1 ZN28 ZN63 – Shone Detail:

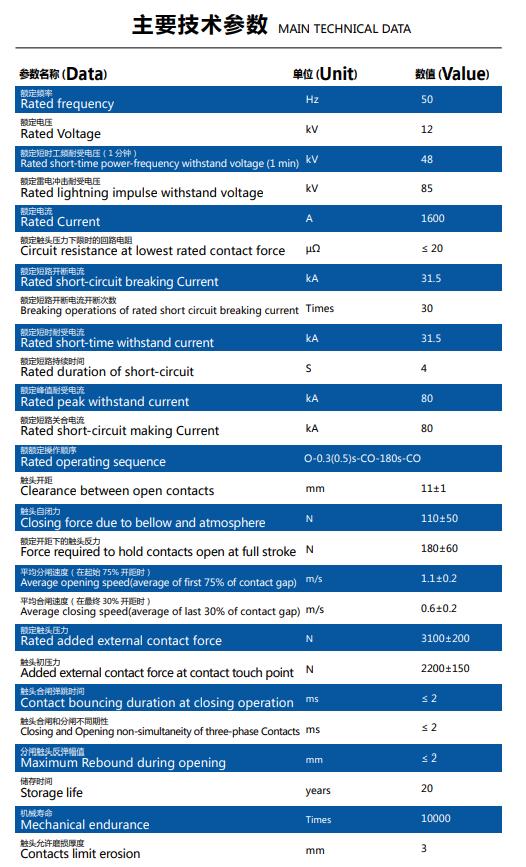

Brief description of the product:

When the fault occurs in the system, the contacts of the breaker are moved apart and hence the arc is developed between them. When the current carrying contacts are pulled apart, the temperature of their connecting parts is very high due to which ionization occurs. Due to the ionization, the contact space is filled with vapour of positive ions which is discharged from the contact material.

The density of vapour depends on the current in the arcing. Due to the decreasing mode of current wave their rate of release of vapour fall and after the current zero, the medium regains its dielectric strength provided vapour density around the contacts reduced. Hence, the arc does not restrike again because the metal vapour is quickly removed from the contact zone.

Pay attention

Strictly control the closing and opening speed of vacuum circuit breaker.

For the vacuum circuit breaker with a certain structure, the manufacturer has specified the best closing speed. When the closing speed of vacuum circuit breaker is too low, the wear of contact will increase due to the extension of pre breakdown time; When the vacuum circuit breaker is disconnected, the arcing time is short, and its maximum arcing time does not exceed 1.5 power frequency half wave. It is required that when the current crosses zero for the first time, the arc extinguishing chamber should have sufficient insulation strength. Generally, it is expected that the stroke of the contact in the power frequency half wave will reach 50% – 80% of the full stroke during circuit breaking. Therefore, the opening speed of the circuit breaker should be strictly controlled. As the arc extinguishing chamber of vacuum circuit breaker generally adopts brazing process, its mechanical strength is not high, and its vibration resistance is poor. Too high closing speed of circuit breaker will cause greater vibration, and will also have greater impact on bellows, reducing the service life of bellows. Therefore, the closing speed of vacuum circuit breaker is usually set as 0.6 ~ 2m / s.

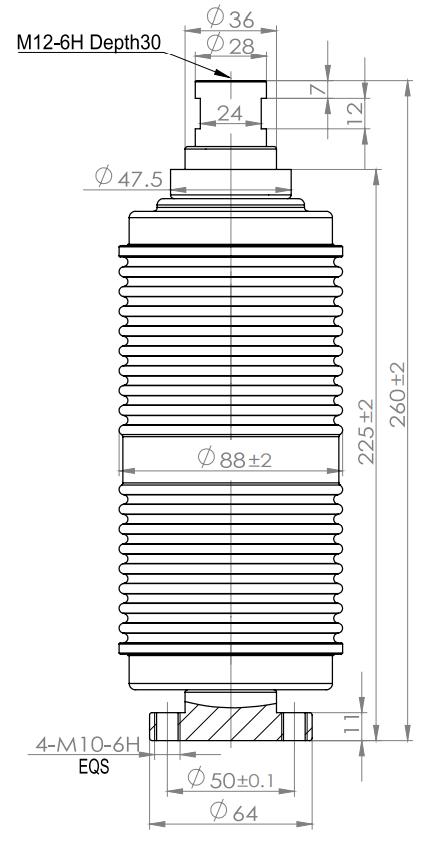

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for China wholesale High Voltage Interrupter Factory – Vacuum interrupter for MV VCB, VS1 ZN28 ZN63 – Shone , The product will supply to all over the world, such as: Qatar, Croatia, Croatia, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.