China wholesale Outdoor Vacuum Switch Factory – Vacuum interrupter for VXG(152) – Shone

China wholesale Outdoor Vacuum Switch Factory – Vacuum interrupter for VXG(152) – Shone Detail:

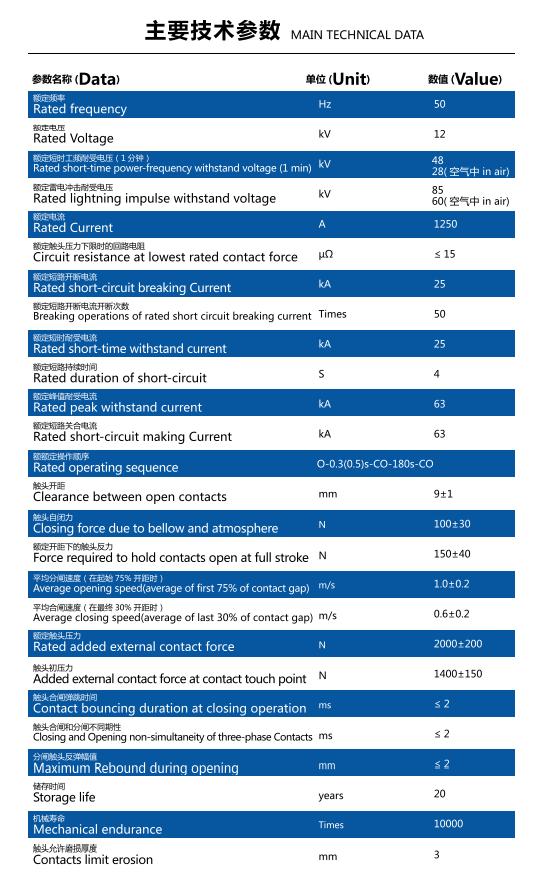

Brief description of the product:

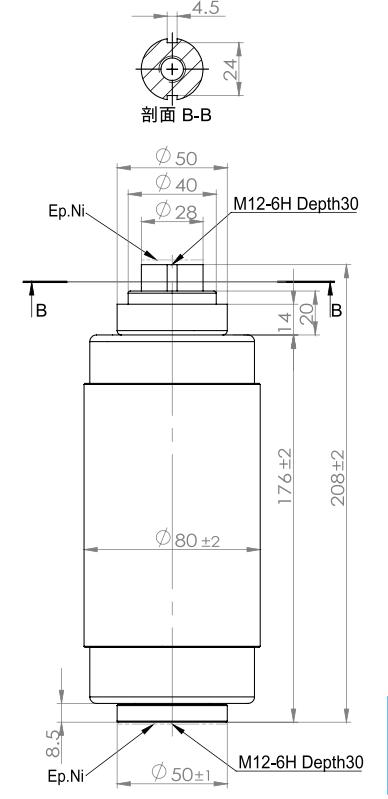

It is mainly applied to the power transmission and distribution control system, and it is also applied to the distribution systems of metallurgy, mine, petroleum, chemical, railway, broadcasting, communication and industrial high frequency heating. Vacuum interrupter has the characteristics of energy saving, material saving, fire prevention, explosion-proof, small volume, long life, low maintenance cost, reliable operation and no pollution. The vacuum interrupter is divided into the use of the interrupter and the load switch. The interrupter of the circuit breaker is mainly used in the substation and the power grid facilities in the electric power department.

Bellows:

The vacuum interrupter bellows allows the moving contact to be operated from outside the interrupter enclosure, and must maintain a long-term high vacuum over the expected operating life of the interrupter. The bellows is made of stainless steel with a thickness of 0.1 to 0.2 mm. Its fatigue life is affected by heat conducted from the arc.

To enable them to meet the requirements for high endurance in real practice, the bellows are regularly subjected to an endurance test every three months. The test is carried out in a fully automatic test cabin with the travels adjusted to the respective type.

Bellows lifetime are over 30,000 CO operation cycles.

Features

1. The contact part is a completely sealed structure, which will not reduce its performance due to the influence of moisture, dust, harmful gases, etc., and it works reliably with stable on-off performance.

2. After the vacuum circuit breaker is opened and broken, the medium between fractures recovers quickly, and the medium does not need to be replaced.

3. Within the service life of the vacuum switch tube, the contact part does not need maintenance and inspection, generally up to about 20 years. Small maintenance workload and low maintenance cost.

4.With multiple reclosing function, it is suitable for the application requirements in distribution network.

Product detail pictures:

Related Product Guide:

We always continually offer you by far the most conscientious customer service, and the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for China wholesale Outdoor Vacuum Switch Factory – Vacuum interrupter for VXG(152) – Shone , The product will supply to all over the world, such as: Iceland, Turin, Bangalore, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.