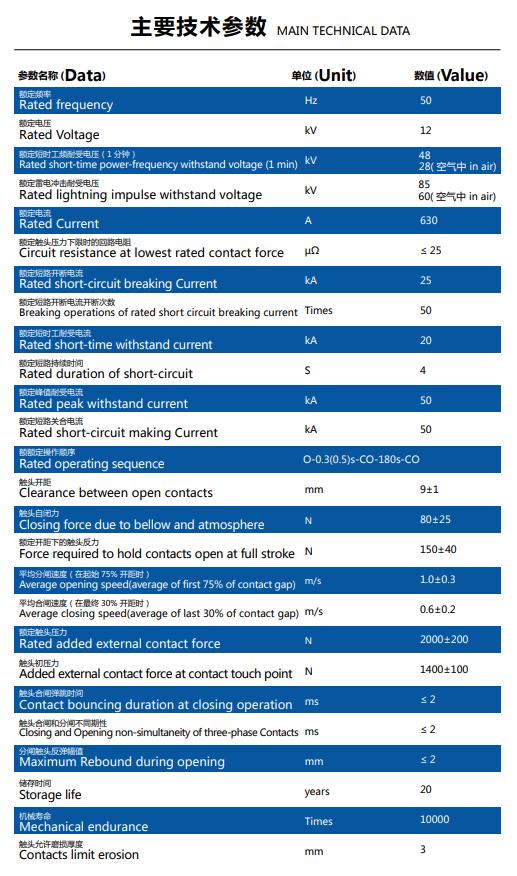

China wholesale Vacuum Interrupter For Load Break Switch Factory – Vacuum interrupter for MV VCB(ceramic shell, Rated voltage: 7.2kV-12kV) – Shone

China wholesale Vacuum Interrupter For Load Break Switch Factory – Vacuum interrupter for MV VCB(ceramic shell, Rated voltage: 7.2kV-12kV) – Shone Detail:

Brief description of the product:

Current chopping in vacuum circuit breaker depends on the vapour pressure and the electron emission properties of the contact material. The chopping level is also influenced by the thermal conductivity–lower the thermal conductivity, lower is the chopping level.

It is possible to reduce the current level at which chopping occurs by selecting a contact material which gives out sufficient metal vapour to allow the current to come to a very low value or zero value, but this is rarely done as it affects the dielectric strength adversely.

High insulating strength: In comparison to various other insulating media used in circuit breaker vacuum is a superior dielectric medium. It is better than all other media except air and SF6, which are employed at high pressure.

When an arc is opened by moving apart the contacts in a vacuum, an interruption occurs at the first current zero. With the arc interruption, their dielectric strength increases up to a rate of thousands time as compared to other breakers.

Pay attention

(1) Measures to prevent overvoltage. Vacuum circuit breaker has good breaking performance. Sometimes when breaking inductive load, high overvoltage is generated at both ends of inductance due to rapid change of loop current. Therefore, for dry-type transformers and other equipment with low impulse voltage resistance, it is best to install overvoltage protection devices, such as metal oxide arresters.

(2) Strictly control the load current.

The overload capacity of vacuum circuit breaker is poor. Since thermal insulation is formed between the contact and the shell of the vacuum circuit breaker, the heat on the contact and the conductive rod is mainly transmitted along the conductive rod. In order to make the operating temperature of the vacuum circuit breaker not exceed the allowable value, its working current must be strictly limited to be lower than the rated current.

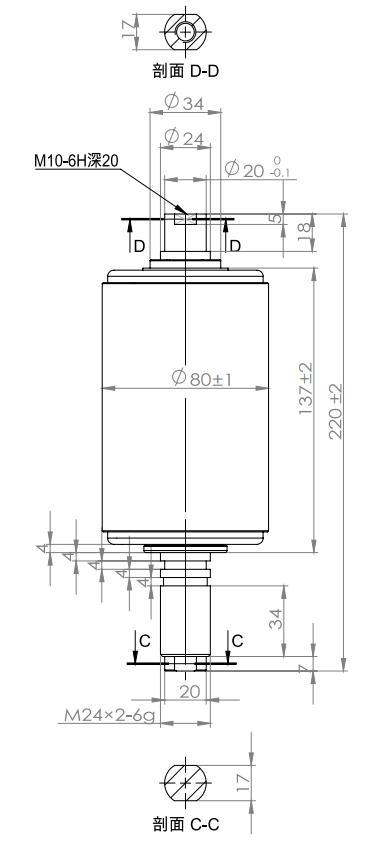

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for China wholesale Vacuum Interrupter For Load Break Switch Factory – Vacuum interrupter for MV VCB(ceramic shell, Rated voltage: 7.2kV-12kV) – Shone , The product will supply to all over the world, such as: Norway, Oman, Melbourne, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.