OEM Power Load Switch Factory – Vacuum interrupter for VXG(150) – Shone

OEM Power Load Switch Factory – Vacuum interrupter for VXG(150) – Shone Detail:

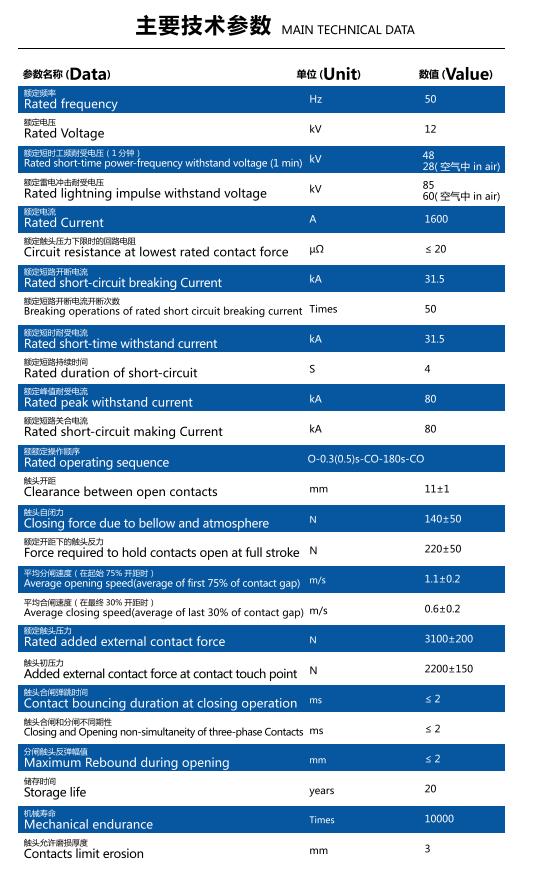

Brief description of the product:

Vacuum interrupter, also known as the vacuum switch tube, is the core component of the medium-high voltage power switch. The main function of vacuum interrupter is to make the medium and high voltage circuit cut off the power supply of the vacuum arc extinguishing chamber of ceramic shell through the excellent insulation of the vacuum inside the tube, which can quickly extinguish the arc and suppress the current, so as to avoid accidents and accidents.

In circuit breakers, vacuum-interrupter contact materials are primarily a 50-50 copper-chromium alloy. They may be made by welding a copper–chrome alloy sheet on the upper and lower contact surfaces over a contact seat made of oxygen-free copper. Other materials, such as silver, tungsten and tungsten compounds, are used in other interrupter designs. The vacuum interrupter’s contact structure has a great influence on its breaking capacity, electrical durability and level of current chopping.

Components of the vacuum interrupter must be thoroughly cleaned before assembly, since contaminants could emit gas into the vacuum envelope. To ensure a high breakdown voltage, components are assembled in a cleanroom where dust is strictly controlled.

After the surfaces have been finished and cleaned by electroplating and an optical inspection of the surface consistency of all single parts has been performed , the interrupter is assembled. High-vacuum solder is applied at the joints of the components, the parts are aligned, and the interrupters are fixed. As cleanliness during assembly is especially important, all operations are done under air-conditioned clean-room conditions.

Vacuum-interrupter manufacturers address these concerns by selecting contact materials and designs to minimize current chopping. To protect equipment from overvoltage, vacuum switchgears usually include surge arresters.

Vacuum arc extinguishing chamber is divided into arc extinguishing chamber for circuit breaker, load switch and vacuum contactor. The arc extinguishing chamber for circuit breaker is mainly used for substations and power grid facilities in the power sector, and the arc extinguishing chamber for load switch and vacuum contactor is mainly used for end users of power grid.

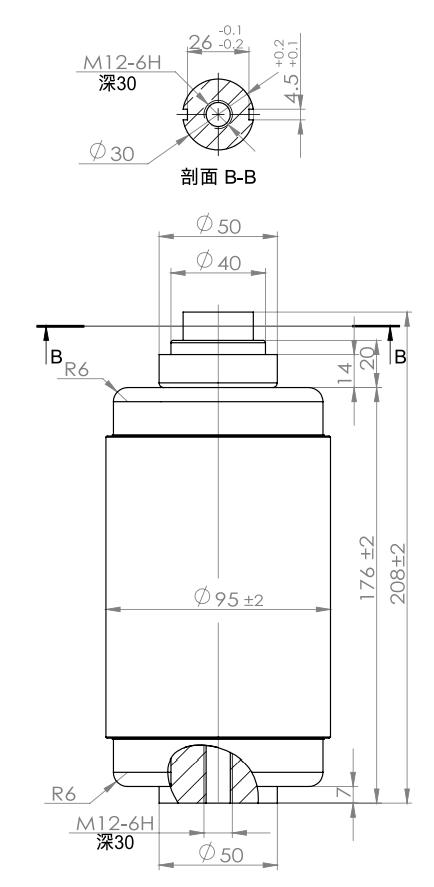

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for OEM Power Load Switch Factory – Vacuum interrupter for VXG(150) – Shone , The product will supply to all over the world, such as: Frankfurt, Germany, Uruguay, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!