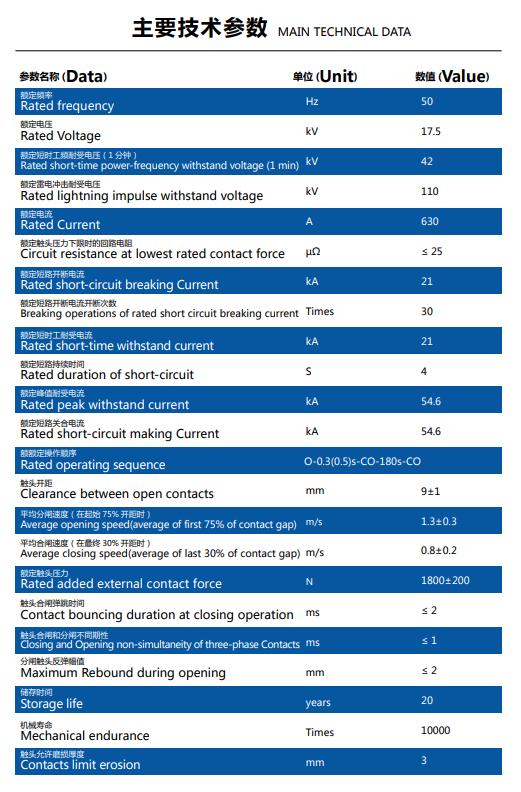

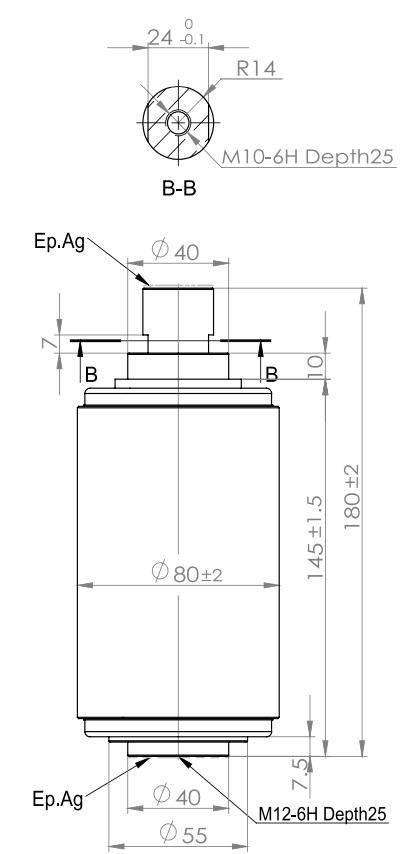

Vacuum interrupter for export TD-17.5/630-21(188)

Brief description of the product:

Subassemblies of vacuum interrupters were initially assembled and brazed together in a hydrogen-atmosphere furnace. A tube connected to the interrupter's interior was used to evacuate the interrupter with an external vacuum pump while the interrupter was maintained at about 400 °C (752 °F). Since the 1970s, interrupter subcomponents have been assembled in a high-vacuum brazing furnace by a combined brazing-and-evacuation process. Tens (or hundreds) of bottles are processed in one batch, using a high-vacuum furnace that heats them at temperatures up to 900 °C and a pressure of 10−6 mbar. Thus, the interrupters fulfill the quality requirement "sealed for lifetime". Thanks to the fully automatic production process, the high quality can be constantly reproduced at any time.

Then, the evaluation of the interrupters by means of the X-ray procedure is used to verify the positions as well as the completeness of the internal components, and the quality of the brazing points. It ensures the high quality of vacuum interrupters.

During forming, the definitive internal dielectric strength of the vacuum interrupter is established with gradually increasing voltage, and this is verified by a subsequent lightning impulse voltage test. Both operations are done with higher values than those specified in the standards, as evidence of the quality of the vacuum interrupters. This is the prerequisite for long endurance and high availability.

Under certain circumstances, the vacuum circuit breaker can force the current in the circuit to zero before the natural zero (and reversal of current) in the alternating-current circuit. If interrupter operation timing is unfavorable with respect to the AC-voltage waveform (when the arc is extinguished but the contacts are still moving and ionization has not yet dissipated in the interrupter), the voltage may exceed the gap's withstand voltage.

Nowadays, with very low current chopping, vacuum circuit breakers will not induce an overvoltage that could reduce insulation from surrounding equipment.