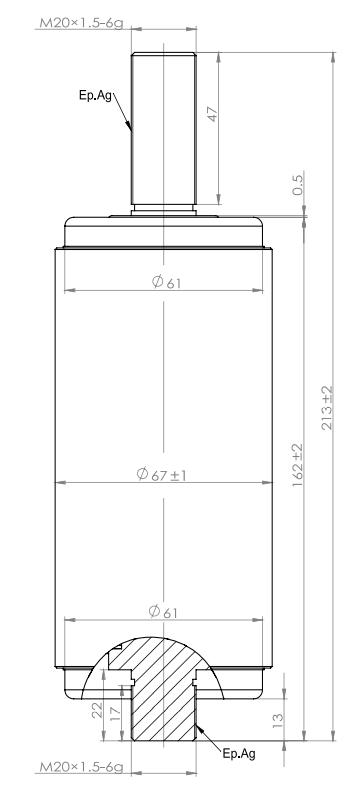

Vacuum interrupter for load break switch(203)

Brief description of the product:

An external operating mechanism drives the moving contact, which opens and closes the connected circuit. The vacuum interrupter includes a guide sleeve to control the moving contact and protect the sealing bellows from twisting, which would drastically shorten its life.

Although some vacuum-interrupter designs have simple butt contacts, contacts are generally shaped with slots, ridges, or grooves to improve their ability to break high currents. Arc current flowing through the shaped contacts generate magnetic forces on the arc column, which cause the arc contact spot to move rapidly over the surface of the contact. This reduces contact wear due to erosion by an arc, which melts the contact metal at the point of contact.

In circuit breakers, vacuum-interrupter contact materials are primarily a 50-50 copper-chromium alloy. They may be made by welding a copper–chrome alloy sheet on the upper and lower contact surfaces over a contact seat made of oxygen-free copper. Other materials, such as silver, tungsten and tungsten compounds, are used in other interrupter designs. The vacuum interrupter's contact structure has a great influence on its breaking capacity, electrical durability and level of current chopping.

When it disconnects a certain amount of current, at the moment of separation of the dynamic and static contacts, the current shrinks to the point where the contacts just separate, resulting in a sharp increase in resistance between electrodes and a rapid increase in temperature, until the evaporation of electrode metal occurs, and at the same time, a very high electric field intensity is formed, resulting in extremely strong emission and gap breakdown, resulting in vacuum arc. When the power frequency voltage is close to zero, and at the same time, due to the increase of contact opening distance, The plasma of the vacuum arc quickly diffuses around. After the arc current passes zero, the medium in the contact gap quickly changes from a conductor to an insulator, so the current is cut off. Due to the special structure of the contact, the contact gap will produce a longitudinal magnetic field during arcing. This magnetic field can make the arc evenly distributed on the contact surface, maintain a low arc voltage, and make the vacuum arc extinguishing chamber have a high recovery speed of post arc dielectric strength, resulting in small arc energy and small corrosion rate.