Vacuum interrupter for MV VCB(ceramic shell, Rated voltage: 7.2kV-12kV)

Brief description of the product:

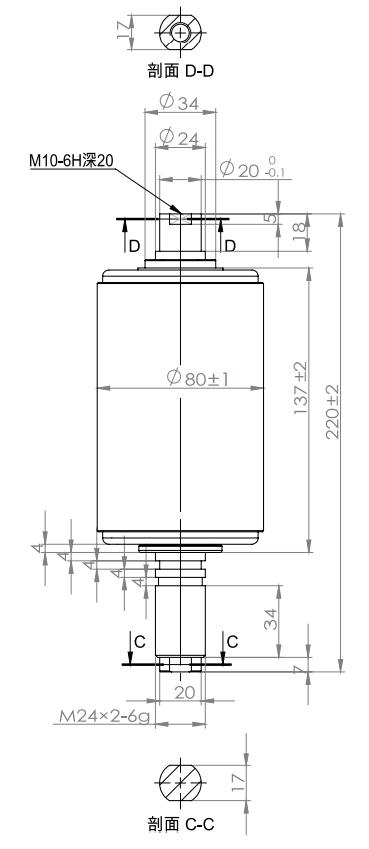

A vacuum interrupter generally has one fixed and one moving contact, a flexible bellows to allow movement of that contact, and arc shields enclosed in a hermetically-sealed glass, ceramic or metal housing with a high vacuum. The moving contact is connected by a flexible braid to the external circuit, and is moved by a mechanism when the device is required to open or close. Since air pressure tends to close the contacts, the operating mechanism must hold the contacts open against the closing force of air pressure on the bellows.

The interrupter's enclosure is made of glass or ceramic. Hermetic seals ensure that the interrupter vacuum is maintained for the life of the device. The enclosure must be impermeable to gas, and must not give off trapped gas. The stainless-steel bellows isolates the vacuum inside the interrupter from the external atmosphere and moves the contact within a specified range, opening and closing the switch.

Although some vacuum-interrupter designs have simple butt contacts, contacts are generally shaped with slots, ridges, or grooves to improve their ability to break high currents. Arc current flowing through the shaped contacts generate magnetic forces on the arc column, which cause the arc contact spot to move rapidly over the surface of the contact. This reduces contact wear due to erosion by an arc, which melts the contact metal at the point of contact.

The density of vapour depends on the current in the arcing. Due to the decreasing mode of current wave their rate of release of vapour fall and after the current zero, the medium regains its dielectric strength provided vapour density around the contacts reduced. Hence, the arc does not restrike again because the metal vapour is quickly removed from the contact zone.

Pay attention:

(1) Measures to prevent overvoltage.

(2) Strictly control the closing and opening speed of vacuum circuit breaker.

(3) Strictly control the contact travel.

(4) Strictly control the load current.

(5) Maintenance cycle of vacuum circuit breaker.